An Introduction to Steel Punching

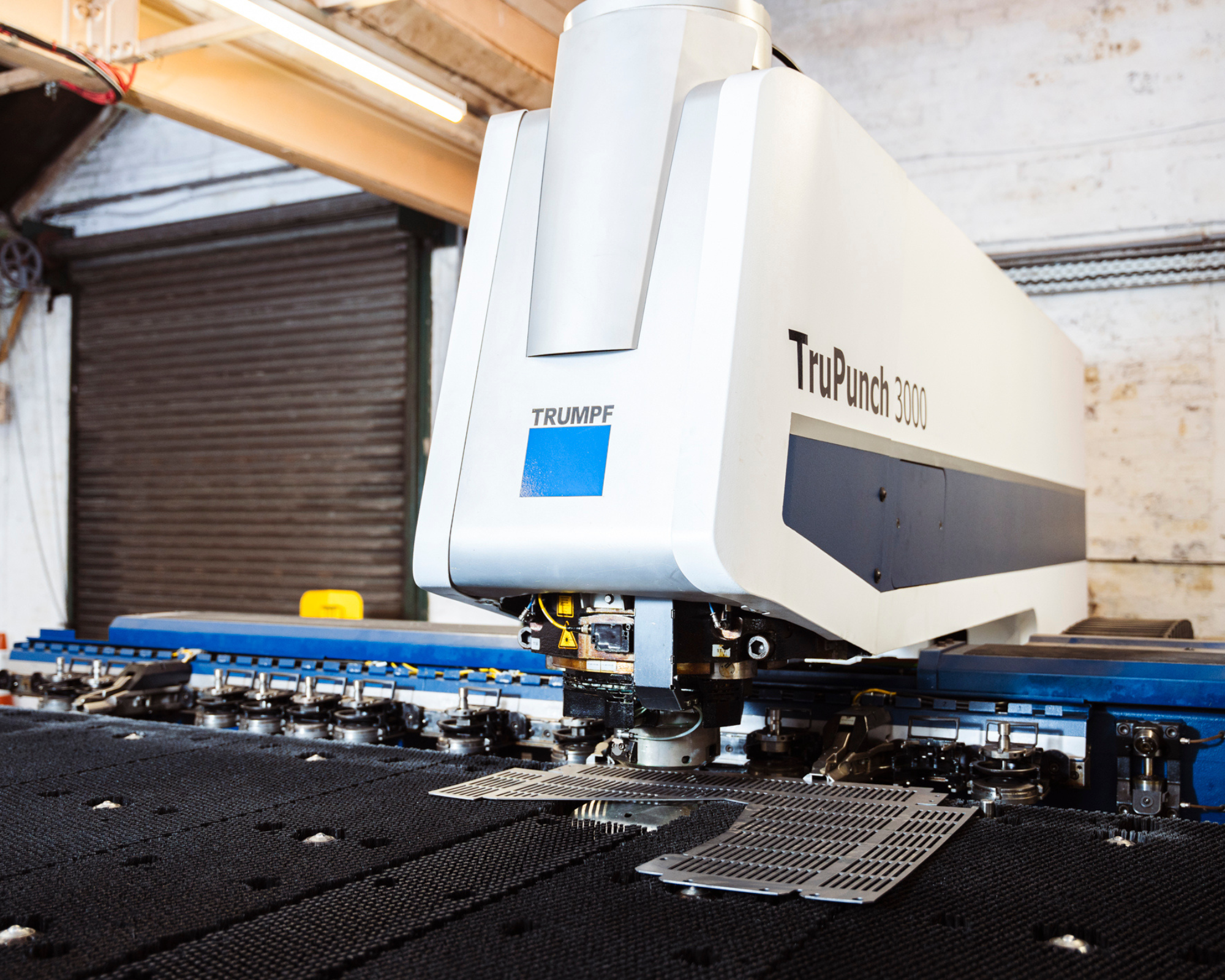

Steel punching is a critical process in modern manufacturing, enabling engineers and fabricators to create clean, precise holes in steel sheets, plates, and studs. Using advanced CNC punch machines, manufacturers can achieve consistent results with speed and accuracy. At Grenville Engineering, CNC punching is an integral service, supporting a wide range of industries through reliable, high-precision production.

Understanding CNC Steel Punching

Unlike traditional methods that rely on manual tools or hydraulic systems, CNC punching automates the entire process. A CNC punch machine is programmed to create holes, slots, and shapes in sheet metal with exact specifications. This includes common applications such as metal hole punching, sheet metal punch hole creation, and producing complex cut-outs for industrial components. The efficiency of CNC punching makes it ideal for both one-off prototypes and high-volume runs.

Why CNC Punching is Essential in Modern Manufacturing

Precision and repeatability are fundamental in any manufacturing setting, and CNC punching provides both. With the ability to produce everything from a single sheet metal punch to multiple punched features on a complex part, this method ensures tight tolerances and consistent quality. The versatility of CNC punch presses allows for the production of round holes, square hole punches for metal, and even intricate slot punch patterns, all from a single machine setup.

How to Choose the Right Punch Design for Your Project

While the machinery is standardised, the tooling used within CNC punch systems can be customised to suit your project. Depending on whether you’re punching sheet metal for electrical enclosures or preparing a metal punch plate for structural components, selecting the correct punch and die set ensures optimal results. At Grenville Engineering, we help clients determine the ideal configuration for their application, whether they require a square sheet metal punch or a specific punch for sheet metal components.

The Advantages of CNC Punching Over Manual or Hydraulic Methods

CNC punching significantly outperforms manual or hydraulic hole punch for metal techniques in terms of efficiency, safety, and precision. The automated nature of CNC punching eliminates the potential for human error and reduces setup time, making it ideal for both short runs and large-scale production. Furthermore, CNC punching enables quick tooling changes and seamless integration with CAD/CAM software, supporting complex project requirements with minimal lead times.

Creating Complex Shapes with CNC Punching

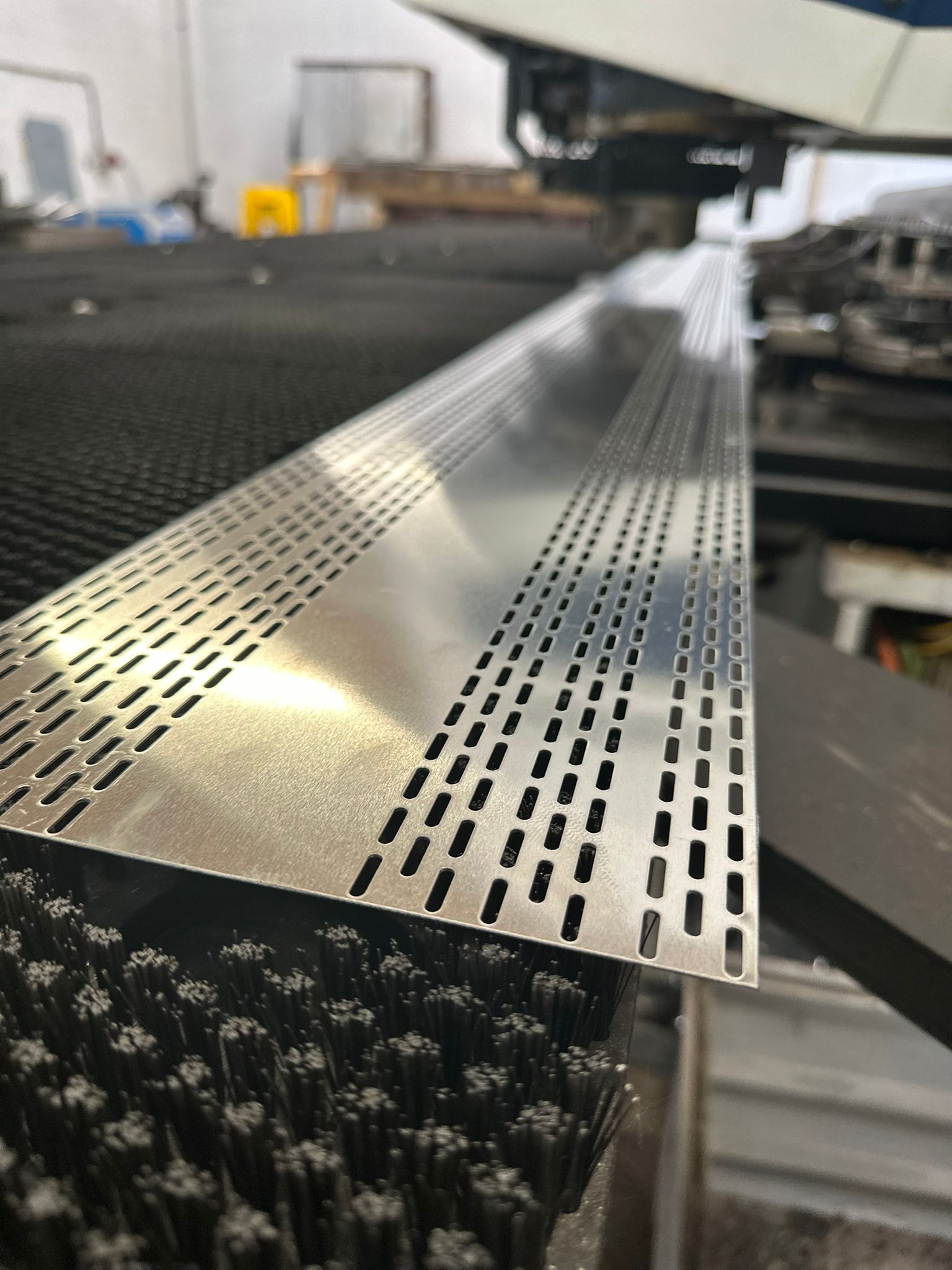

CNC technology allows for much more than simple round holes. Tools such as square punch for metal or slot punch for metal can be incorporated into the CNC turret, enabling the creation of bespoke features tailored to client designs. This capability is especially valuable in sectors such as construction and electronics, where specific cut-outs are often required to accommodate fittings, fasteners, or wiring systems.

Avoiding Common CNC Punching Issues

Even with automated machinery, certain challenges can arise. Issues like sheet misalignment or excessive tool wear can compromise the final output. To maintain quality, operators at Grenville Engineering follow rigorous procedures, ensuring that each metal sheet is correctly positioned and that all punch tools are properly maintained. This attention to detail helps avoid problems such as burr formation, inconsistent punch depth, or tool misfires.

Maintaining CNC Punch Tools

Proper tool maintenance is essential for continued precision in CNC punching. At Grenville Engineering, we routinely inspect and service all punch and die sets, ensuring clean cuts and prolonging tool life. This includes sharpening tools, checking for signs of fatigue, and applying lubrication where necessary. Regular maintenance prevents downtime and supports the high-quality standards expected in sectors such as automotive, construction, and heavy industry.

Precision Punching with CNC Technology

CNC punching offers a powerful, efficient, and accurate solution for modern sheet metal fabrication. From metal stud punches to complex slot configurations, Grenville Engineering delivers expert CNC punching services designed to meet strict quality and regulatory standards. By choosing CNC over manual methods, manufacturers benefit from faster turnaround times, reduced waste, and unparalleled consistency. To learn more, explore Grenville Engineering’s metal punching capabilities today.