Precision CNC Machining Services For Metal Components

Achieve Perfection in Fabrication through Our Precision Sheet Metal Machining Services

Fabrication Services > Machining

A reliable choice for precision machining and comprehensive fabrication solutions

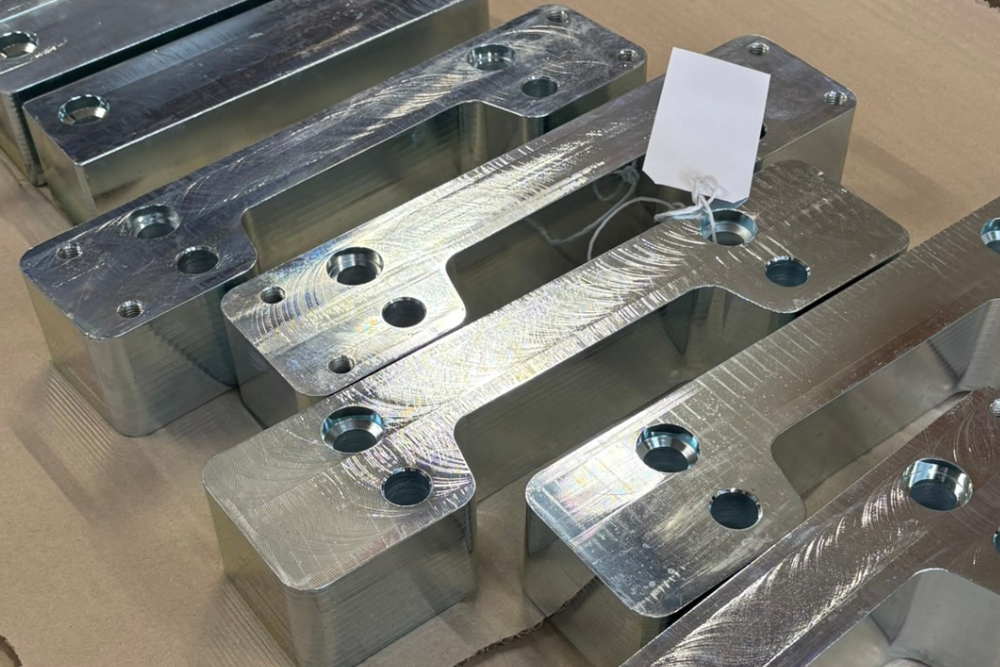

We offer a complete in-house precision machining service, delivering high-quality components with intricate detail and exceptional accuracy. Our machining workshop now features two Hurco CNC Vertical Machining Centres, strengthening our capacity to meet increasing customer demand and complex project requirements.

Our latest investment, the Hurco VM20i 3-Axis Machining Centre, is a significant upgrade. It features a 20-bar through-spindle coolant system and swarf auger. These enhancements support faster drilling speeds, cleaner machining processes, and reduced daily maintenance, boosting overall efficiency for both low-and high-volume work.

Whether you need one-off prototypes or large production runs, our team is equipped to handle your project with speed and precision. The advanced features of our Hurco machines allow us to achieve tight tolerances and manufacture complex geometries consistently, ensuring every part meets our high standards for quality.

We also offer CNC Turning and additional machining support through our trusted affiliate, Regina Industries, giving us the flexibility to deliver a wide range of components across multiple industries.

As part of our full-service fabrication offering, our metal machining capabilities complement our laser cutting, metal forming, welding, and assembly services, making Grenville Engineering your trusted one-stop engineering partner.

Why Choose Grenville Engineering

- High-Quality CNC Precision Machining

- Cost-Effective Production Process

- Comprehensive Fabrication Solutions

- Versatility in Machining Capabilities

- Quality Assurance – ISO 9001

If you have a Machining services enquiry call us today on 01782 577 929 or email us at: sales@grenville-engineering.co.uk

Precision Machining

Hurco VM20i CNC Machining Centres

Our two Hurco VM20i 3 Axis CNC Machining Centres form the core of our advanced precision machining capability. Designed for speed, reliability, and exceptional accuracy, both machines feature a rigid fine grade cast iron frame for maximum stability and performance.

Each machine is equipped with a 12,000 RPM spindle, Yaskawa Sigma V Servos, and an automatic 24 tool changer to support efficient, high quality production. The latest machine, installed in August 2025, includes a 20 bar through spindle coolant system and swarf auger, enabling faster drilling speeds, cleaner machining, and reduced maintenance. Together, these investments enhance our ability to deliver complex components to tight tolerances across all metal fabrication and engineering projects.

XYZ CT 65 LTY Turning Centre

Our XYZ CT 65 LTY Turning Centre further expands our in-house CNC machining services, offering exceptional turning performance for precision-engineered components. Featuring a 65 mm bar capacity, 250 mm chuck, and Y-axis milling capability, this advanced turning centre allows for complex multi-operation machining in a single setup.

With its robust construction and Siemens 828D control system, the CT 65 LTY delivers outstanding accuracy, repeatability, and surface finish. This machine enables faster lead times and greater flexibility for both prototype and production work, strengthening our commitment to complete precision engineering and metal fabrication solutions.

Lathes and Drilling Machines

Our machining department includes precision lathes and drilling machines that support our complete CNC machining and metal fabrication services.

Our jobbing lathes use hardened cutting tools guided by manual or CNC controls to remove material from metal components with accuracy and consistency. This ensures smooth finishes and precise dimensions across a variety of projects.

Our pedestal drilling machines feature a strong upright column and stable base for accurate, repeatable results. Bench drills are used for smaller or lighter components, providing the same level of precision and reliability. Together, these machines play an essential role in delivering high quality components and maintaining the accuracy and craftsmanship expected from Grenville Engineering.

Get in touch today

& find out how we can help

your business

Contact us today to find out more about our services & how we can help you.

Alternatively you can call us us on 01782 577 929

or email us at sales@grenville-engineering.co.uk

Request a callback today

Sheet Metal Forming Machinery FAQs

What precision sheet metal forming services does Grenville Engineering provide?

At Grenville Engineering, we specialise in precision sheet metal forming using advanced fabrication machinery. We transform flat metal sheets into high-precision components using superior materials, skilled engineers, and proven fabrication processes.

Whether you require bespoke prototypes or high-volume production, our facility is equipped to deliver exacting results. We focus on producing high-quality components that meet specification, perform as intended, and are delivered on time, making us a dependable sheet metal fabrication partner.

What is sheet metal forming and why is it important?

Sheet metal forming is a core manufacturing process used to shape flat metal stock into three-dimensional components for finished products and assemblies. Using controlled forming techniques, we precisely shape raw materials, enabling the production of everything from simple brackets to intricate enclosures.

Our advanced forming processes include bending, folding, rolling, and punching, with each technique selected to meet the exact specification of your component. This ensures accuracy, repeatability, and tight tolerances for seamless integration into your assemblies.

How does advanced fabrication machinery improve precision and efficiency?

By investing in state-of-the-art metal working machinery, we deliver tangible benefits for your projects. Our equipment enables highly accurate bends, folds, and shapes across a wide range of metals, making it suitable for both simple and complex multi-step components.

Key benefits include exceptional accuracy for tight tolerances, high-volume repeatability for consistent production, and reduced handling through automated processes that improve efficiency and reduce manual labour.

What sheet metal forming machinery and capabilities do you offer?

We operate a diverse fleet of metal fabrication machine tools, each serving a critical function in the forming process. Our CNC-controlled press brakes provide exacting bends with outstanding accuracy and repeatability, ideal for chassis, brackets, and panels.

Rolling machines produce cylindrical and curved shapes such as tubes and cones, while folding machines handle long folds and multiple bends efficiently. In addition, our high-speed CNC punching machines create holes, slots, and cut-outs quickly and accurately.

What materials and industries do you work with?

We work confidently with a wide range of materials, including mild steel, stainless steel, aluminium, galvanised steel, high-strength steels, copper, and brass. This versatility allows us to support a broad industrial base, including automotive and transport, construction, HVAC, agriculture, and precision engineering.

Our sheet metal fabrication services are used for a wide range of engineered components, from vehicle housings to structural brackets.

Why choose Grenville Engineering for sheet metal fabrication?

Grenville Engineering offers a complete, in-house sheet metal fabrication solution designed for quality and speed. As an ISO-certified manufacturer, our processes are rigorously audited to ensure the highest standards. We manage everything from initial design and prototyping through to large-scale fabrication and final assembly, including laser cutting, welding, and finishing. Our skilled engineers support prototypes, small batch runs, and high-volume production with fast turnaround times and consistent quality assurance.

Ready to start your next project?

Contact us today for a consultation or a detailed quotation. Let our expertise in precision sheet metal forming and fabrication support your component success.

Find out how we can help today

Call Grenville Engineering on 01782 577 929

or email us at sales@grenville-engieering.co.uk