At Grenville Engineering, laser cut steel is more than a service – it’s a craft honed over four decades. We blend technical know-how with a personal approach to deliver laser cut steel and stainless steel solutions that stand out for quality, accuracy, and reliability. Our team’s experience means we can adapt to the most demanding projects, providing peace of mind from start to finish.

Precision You Can Depend On

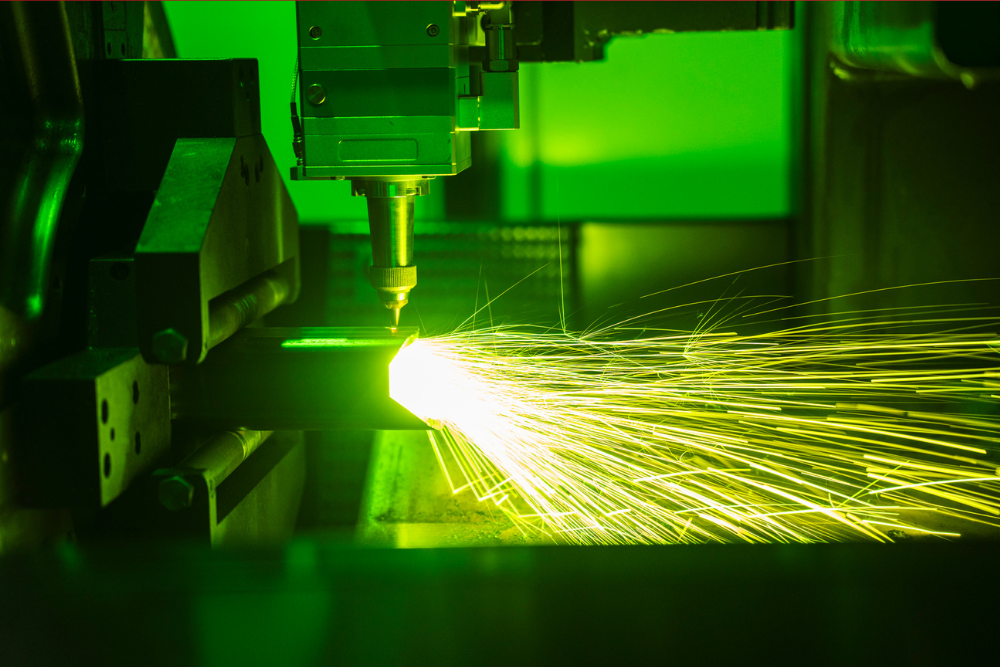

Our investment in cutting-edge laser machinery means we can cut even the most complex profiles with clean, precise edges. Whether you need a laser cut stainless steel sheet for a cleanroom environment or bespoke mild steel parts, we deliver components that meet your exact needs while reducing waste and minimising lead times. Our facility is equipped to handle both small-batch prototypes and high-volume production, ensuring scalability as your project grows.

Our expert team understands how crucial tight tolerances are in today’s competitive industries. We apply rigorous quality checks at every stage, ensuring your laser cut steel parts arrive exactly as specified. This attention to detail helps reduce assembly times, eliminate rework, and keep your projects moving forward with confidence.

Supporting a Diverse Range of Industries

From automotive and construction to energy, agriculture, and aerospace, clients across the UK rely on our laser cut steel sheet services to keep their operations efficient and competitive. Our experienced engineers work side by side with your team, offering practical advice, design support, and solutions that save time and cost. With every project, we strive to add value by optimising designs for laser cutting, which often reduces unnecessary material use and enhances performance.

Our customers value our ability to meet demanding deadlines without compromising quality. Whether it’s a one-off prototype, small production run, or ongoing supply contract, Grenville Engineering has the capability and capacity to deliver precision laser cut stainless steel and steel parts when you need them most.

Comprehensive In-House Fabrication Solutions

We don’t just offer laser cut stainless steel near you – our in-house fabrication team supports every stage, from material sourcing and design consultation to folding, welding, powder coating, and assembly. This integrated approach reduces lead times, improves quality control, and ensures your project remains on schedule. Our highly trained staff and state-of-the-art laser cutters maintain exceptional standards across every order, big or small, giving you confidence in the finished product.

Our commitment to continuous investment in technology and staff development allows us to stay ahead in the metal fabrication industry. We’re proud to hold ISO 9001 certification, which underpins our quality management systems and demonstrates our dedication to excellence in everything we do.

A Trusted Partner for Your Business

At Grenville Engineering, we see ourselves as more than a supplier; we’re your long-term partner in success. Our dedication to precision, reliability, and customer-focused service has made us a leading name in steel laser cutting across the UK. By working collaboratively and building lasting relationships, we tailor every solution to your unique needs. Whether you require stainless laser cutting for architectural features, detailed machine parts, or repeat production runs, our team is ready to deliver on time, every time.

We invite you to tour our Stoke-on-Trent facility and see our advanced laser cutting and fabrication equipment in action. Our friendly, knowledgeable team is always ready to discuss your requirements, provide expert advice, and develop a plan to bring your designs to life.

Discover how our steel laser cutting expertise can transform your next project. Explore our metal fabrication services or contact us today to find out how Grenville Engineering can bring your ideas to life with precision, care, and over 40 years of trusted experience.