New Installation Supports Growth and In-House Manufacturing Focus

We’re pleased to announce the installation of our second Hurco CNC milling machine, the VM20i 3-Axis Machining Centre. This machine expands our machining capabilities and supports our commitment to increased automation.

Following the success of our first Hurco machine, commissioned in July 2024, this latest investment is a direct response to continued growth and increasing demand from customers, particularly within the renewable energy sector, all while maintaining the high standards we’re known for.

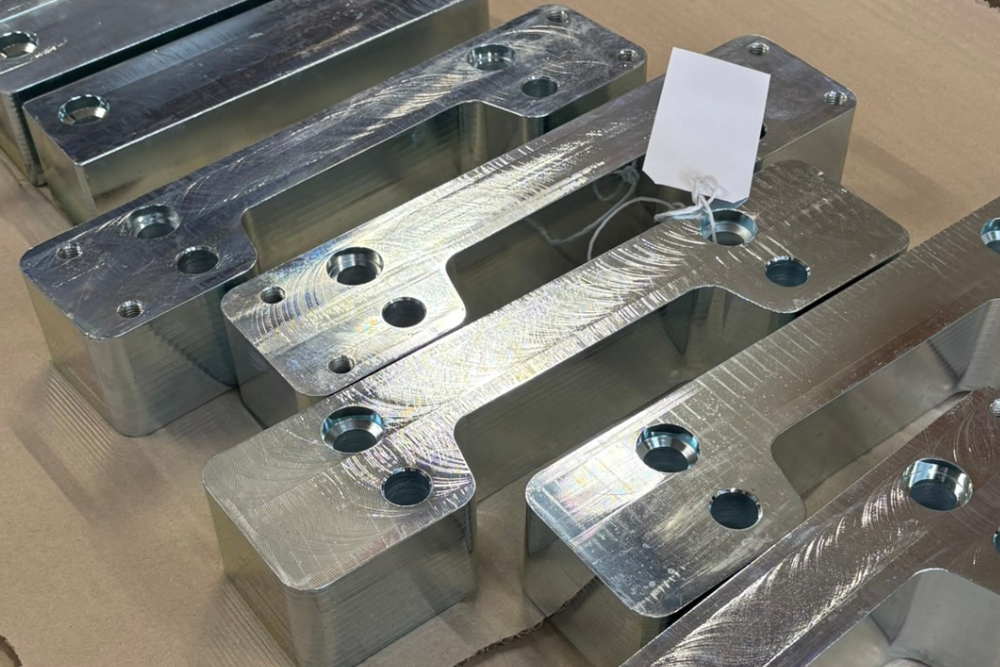

The VM20i includes a 20-bar through-spindle coolant system and a swarf auger. These features improve performance and efficiency, enabling faster drilling speeds, cleaner machining processes, and reduced daily maintenance for our operators.

We’ve been genuinely impressed with the Hurco machines. Their build quality, advanced features, and excellent surface finishes have greatly impacted our workflow.

Grant Barratt, our Purchasing Director, explains the decision behind the investment:

“The main driver behind this was the uplift in customer demand. We’ve been pleased with the performance of our first Hurco, so adding a second was a natural next step to keep production in-house and maintain the high standards we promise our customers.”

This new machine will primarily be used for high-volume batch work, but it’s equally well suited for low-volume, complex components that require high tolerance and a fine surface finish, making it a flexible addition to our operation.

“This machine also supports our wider growth strategy,” Grant added. “It aligns with our focus on automation, which will be one of the key drivers of our future success. Investing in the right machinery and our people ensures we’re in the best position to meet evolving customer needs.”

The VM20i brings four tonnes of precision milling to our workshop, with a generous table size of 1168 x 508 mm, 15.0 kW of spindle power, and capacity for 24 tools up to 80mm in diameter and 250mm in length.

With two Hurco machining centres now in operation, our capacity and flexibility continue to grow, further enhancing our full-service offering in laser cutting, metal forming, welding, machining, and finishing.