What Does Full Service Metal Fabrication Really Mean?

When businesses search for a metal fabrication supplier, the initial requirement is often focused on a single process. Laser cutting, welding or forming. While sourcing individual services can work in isolation, managing multiple suppliers across different stages of production often leads to delays, inconsistent quality and increased costs.

Full service metal fabrication removes these challenges by bringing every stage of the fabrication process under one roof. At Grenville Engineering, we provide an end to end sheet metal fabrication service, supporting customers from early design input through to fabrication, assembly and final delivery of complete components and products.

This integrated approach allows us to act as a true manufacturing partner, not just a supplier for one specific process.

Metal Fabrication in Practice

Metal fabrication goes far beyond cutting and welding. In practice, it requires careful planning, precise execution and close coordination between multiple processes. When these stages are split across different suppliers, even small misunderstandings can impact quality, lead times and overall project efficiency.

A full-service fabrication partner manages the entire workflow as a single, connected process. From the initial design discussion, every decision is made with the finished component in mind. This results in smoother production, fewer delays and consistent quality at every stage.

Comprehensive In-House Fabrication Capabilities

Grenville Engineering offers a complete range of in-house metal fabrication services, allowing us to maintain full control over quality, scheduling and delivery.

Our capabilities include:

- Design and engineering support to optimise components for manufacture

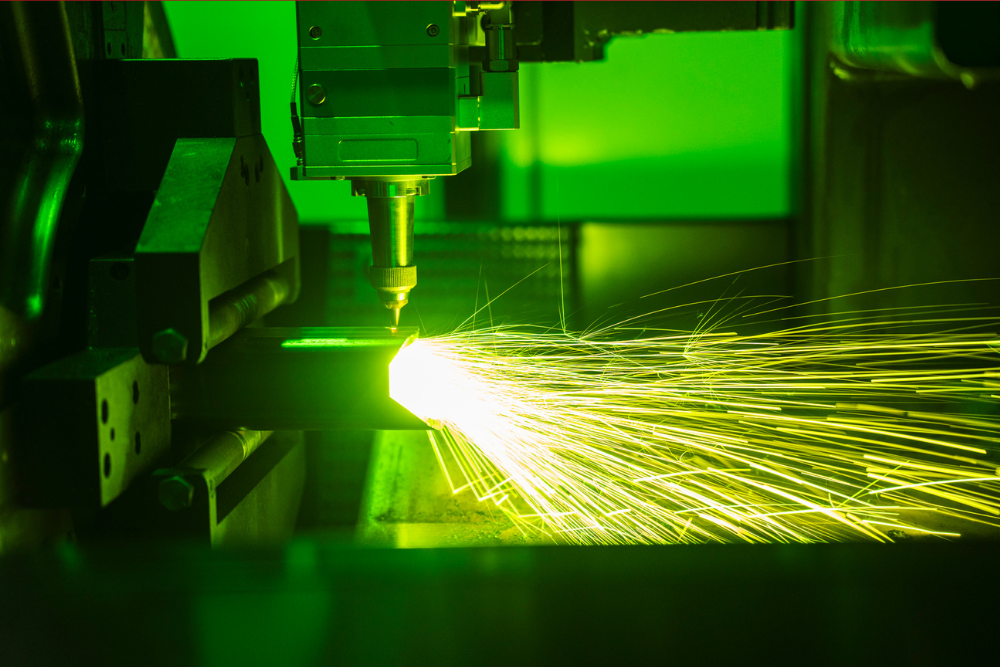

- Laser cutting for accurate, repeatable sheet metal parts

- Punching for efficient sheet metal processing

- Forming and bending to precise tolerances

- Welding carried out by skilled, experienced fabricators

- Assembly of finished components and products

- Logistics and delivery using our own vehicles and trusted partners

- Kanban stock holding to support ongoing production requirements

By keeping these processes in-house, we eliminate unnecessary handovers and ensure every stage of fabrication aligns seamlessly with the next.

Single source contact – Having a single point of contact i.e. Account Manager can help to speed decision making and reassurance that the manufacturing problem will be dealt with.

Trust – Customers trust in transparency and getting the best out of the customer/supplier relationship

Specialised skills/capabilities – Dealing with a fabrication company that has relevant skills in manufacturing your product i.e. Stainless steel dedicated facility, CE marking accreditation, traceability

Collaboration – Bespoke projects require a partnership approach from both the customer and supplier as this often involves in depth conversations and drawing iterations to maximise on the product quality/performance.

Technical Expertise – In house technical expertise that can adapt and improve design for cost saving and manufacturing efficiencies.

Why Keeping Fabrication Under One Roof Matters

One of the key advantages of full-service metal fabrication is consistency. When all processes are managed internally, the same quality standards are applied throughout production.

Potential issues can be identified early and resolved quickly, often before they impact the finished product.

Efficiency also improves significantly. Without reliance on external suppliers, lead times are reduced, and production schedules become more predictable.

Design changes or urgent requirements can be accommodated without restarting the process or coordinating multiple third parties.

For customers, this means clearer communication, fewer delays and confidence that their project is being managed as a complete solution rather than a series of disconnected tasks.

A Collaborative Approach to Every Project

At Grenville Engineering, we believe the best results come from close collaboration. We work alongside customers from the earliest stages of a project, offering practical input and engineering insight to refine designs and improve manufacturability.

This collaborative approach ensures each solution is tailored to the customer’s specific requirements, whether the goal is improved efficiency, reduced cost or enhanced durability.

By understanding the end use of every component, we are able to add real, measurable value throughout the fabrication process.

Over 40 Years of Manufacturing Experience

As a long-established family business with more than 40 years of manufacturing experience, Grenville Engineering has built a strong reputation for reliability, quality workmanship and long-term partnerships.

Our experience allows us to support customers across a wide range of industries and project sizes.

We understand the pressures faced by modern manufacturers and work proactively to deliver consistent quality and dependable turnaround times.

A Fabrication Partner You Can Rely On

Grenville Engineering is ideally suited to businesses looking for a reliable, long-term metal fabrication partner rather than a supplier for a single process. Our full service fabrication capability, combined with our collaborative approach and decades of experience, enables us to support customers as their requirements evolve.

By choosing a complete fabrication partner, customers benefit from improved quality control, shorter lead times and a more efficient production process from start to finish.

If you are looking for a metal fabrication partner who understands your business and delivers complete, well-managed solutions, Grenville Engineering is ready to support your next project.

Get in Touch and find out how we can support you with our added value service sales@grenville-engineering.co.uk